|

Making A

Laughing

Buddha

- And

Then

A Ponytailed

Barbie

Bust:

-In

the

workshop

There really isn’t everything in the world to say about creating a figure from scratch without going into a full course on sculpture – which I don’t feel like I can, having near-zero formal training/schooling in sculpture (some drawing in my art education, something for which I have no overwhelming talent, but virtually no sculpture, alas) and nothing but a certain head for 3D shapes and years of experience practicing and self-teaching and getting better.

What

I can do is talk about my

process

and technique and materials in hopes of providing at least that much help to artists and aspiring

ones. I take a lot

of pictures of what I’m working

on for a

thread on the forum I run, so I’ll see what I

can say to go with the pictures I took of two projects earlier this

summer.

-Up

front before

I proceed, I think it’s important to mention that an enormous part of

the work

of doing art is the thinking you

do

about it, both before you even start and during the actual crafting,

mostly

while you’re doing something else that isn’t terribly engaging. I come to a lot

of creative decisions and

have ideas for how to tackle crafting problems while I sit with my cats

outside

during feeding – honest. I

do a lot of

art thinking in bed, in the bathroom, while cooking – you name it. My subconscious is a

powerful thing, and the

back of my head is a productive place – my daydreams dream about what

I’m

working on, on a good day, and sometimes solutions come to me, sorta

for free.

…

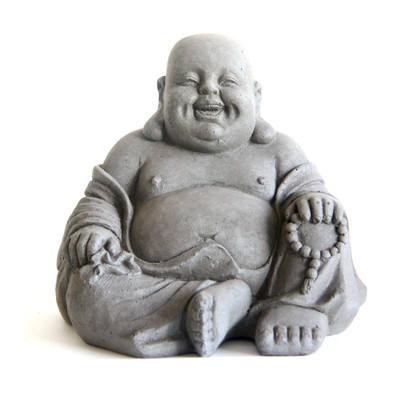

So,

one of the ideas

I’d had for a candle towards the end of my last high

creative-energy/productivity cycle was one of those laughing Buddha

statues. My sister

had one when I was a

kid, and he had a lot of cheery charm.

Sis’

looked a

bit like this:

-It’s

worth

pointing out, too, before I go further, some other factors informing my

creative decisions; I thought of the laughing Buddha as part of a

series of candles that I would be casting copies of.

The mold was to be latex, and the vaguely

conical outline of the figure, wide at the bottom and narrow on top

with no

tight constrictions to have to stretch the latex over during demolding,

was

ideal. Latex

painted on in multiple

layers can take the heat of melted wax, though it ages the latex

faster, and

it’s a stretchy, flexible, material, but the less stress on the mold,

the

better for its longevity, especially

when it has to take some heat, too.

(They last a lot longer casting plaster than melted wax.)

The

first thing

I did physically was to squeeze an

aluminum foil core into a cursory shape of a rotund seated, robed,

figure, see

below to the right in two pictures of casting the previous project.

-That core’s actually not very good, by the way – too much head and not enough body. I squeezed the head as small as it would go, and seem to recall adding foil to the bottom – and still ended up with an extra-thick layer of Sculpey, the polymer baking clay I use to craft most of my originals, at the bottom.

The whole point

of a foil core is that foil’s cheaper than Sculpey and easier to

restock, and that

polymer baking clays bake more reliably when they’re not solid forms

over a

quarter inch thick.

And that brings

us to the frustrating part of a sculpture tutorial; the brain enters a

somewhat

timeless state when you’re in the zone with the shaping, it’ll take

forever to

stop and take any photos, and it’s difficult to describe. To say that I spread clay

over the core and

then moved it around for about an hour until it began to resemble what

I’d

imagined is true, accurate, and very

unhelpful.

Someday, I should set up a camera to take time-lapse video

while I craft

a simple figure. That

might prove to

have more educational value than having to, basically, skip the

hardest/most important

part…

So this is what

I posted on the forum the next morning…

(Mold-making

I go into

somewhat in the next section, but I need to dedicate a page to it.)

Still, much improved in the detailing, not least the proportions of the legs – but the features never came to look particularly Asian and the laughing expression was probably better in the first draft, for all that the details of the features became more regular, sloppy nose notwithstanding. It was a credible expression of what I imagined, and the robe drapery, something I’d never tried before, came out OK. I’m fairly proud of this one, while aware of some room for improvement.

-And

here’s some shots of

the wax castings I did of him, all with a different Barbie bust than

the one I talk about making next…

The Trouble With Barbie’s Neck…

This

is a 20

year-old (dirty) resin bust I did, copied off an actual Barbie with a

hairdo I

made in the style of a mid-60s release.

That skinny neck has been the destruction of at least one

latex mold and

caused the snapping off of the head of a number of castings during

demolding, and part of the inspiration

behind the big hair Barbie keeping Budai company in the photos just

previous

was thinking about a workaround in the form of hair that went all the

way down

to the shoulders…

-That

one was actually

made on this one with hair added, and one of the problems with it was

copy

degradation. (Another

was that the big

Doris Day ‘do still left a deep constriction at the shoulders where it

turned

in and met, and while a huge improvement on the bare neck, it was still

very hard on the longevity of the

mold.) So when a

Barbie with her hair in a loose ponytail

started kicking her way out of my subconscious, I went back to the

original,

for the higher fidelity of a first-generation copy of the actual Barbie

parts.

(Why

Barbie

-from a middle-aged straight man- has to do with having a Barbie artist for a sister…)

-Then I spread

the modeling clay

over her bald head and roughed in the shape I wanted for the hair:

I see in

retrospect that this is when a slight tilt to her head crept in without

me

realizing until the first cast was demolded – a happy accident, because

I liked the head tilt. It gave her a little more

perky personality,

and was a further difference from the other two custom-hair Barbie

busts…

(However, I’d

already made a fundamental error; I’ll spoil this part of the narrative

in

revealing that gathering the hair at the

back of the neck caused the

narrow-point/bottleneck with demolding

that the hairdo was intended to avoid.

It was compounded when she slumped over in front off the

dehumidifier and

hit her head; while I was fixing the minor dent in the clay, I bulked

out the

ponytail on her back below the gather, which was fine – but I also

added

non-trivial volume above the

gather,

closer to what I’d originally envisioned, and made the hair band a bit

wider in

the process, which resulted in the deepest part of the hair being

directly

opposite the chin, with two constrictions behind the throat. -More on that, and pics, below.)

...Next, I built up plasticine around the rubber band to make a base for the latex mold and started dabbing on layers of latex...

(I’ve

found no

better way of applying latex than to dip a finger in and dab on the

subject –

brushes and sponges and such are hopelessly fouled with bits of random

dried latex after a single use, no matter what efforts to clean them.)

The modeling

clay I’d built up for the bottom of the mold had softened in the heat

in front

of the dehumidifier and slumped away after several coats, so I took a

Pringles

can lid I’d used to suspend other Barbie figurine molds and cut a

little more

out of the hole to accommodate the ponytail and carefully

worked it into place underneath and soldiered on with the

dabbing layers and waiting for them to dry. Note that more of

her

is tied up now, to stablize the body when I set her out to dry and

avoid nasty surprizeswith her flopping over.

Time passes, and

I’ve made considerable progress on the pig snout in between dabbing new

layers

on Barbie, and the mold for the figure of my niece has just gpotten a

plaster mother

mold to hold it shut during casting…

I’d started

Ponytail Barbie on 18 July, and finished and started the mold the next

day, to

give you an idea of the latex mold-making timeframe.

On the first of August, I posted:

(An

artist friend had suggested

molds made of silicone calking putty shortly after I committed Ponytail

Barbie

to latex – I’m still mastering working with that, but have found it a

nice –and

cheap- compromise with the slowness and lack of longevity of latex, and

the

very high price of something like Amazing Mold Putty.)

14

minutes later, I posted:

“...Snapped her head off already..."

(Not as big a

disaster as it may sound.

White glue works fine, provided there was no great chipping

around the edges of

the break -and you're patient enough to let it dry properly- and

plaster can be

painted on with a brush for covering boo-boos, too.)

"Well, after several minutes of

struggling with it, I cut the mold to preserve

the figure w/o further damage.

"The facial features came out

exquisitely preserved, though the shoulder seams

need covering, as of course, does the crack around the neck.

I'd like to

add finer texture to the hair, too, so it doesn't look like

dreadlocks.

The mold/casting flaws of any significance are all in the hair, and

thus,

easily concealed.

"I don't know how the tilt of the head

got in there -it's not from the break-

but I think I love it.

"I was very foolish to do a loose

ponytail like that -with the gather resting so

low at the base of the neck and hair belling out above it opposite the

chin- in

a design intended to minimize

the demolding bottleneck troubles; I think I made it worse.

"-But I believe I can make a mighty fine calk mold on this that will be no trouble at'all to work with..."

---

Latex molds are

one-piece sheaths of

more-or-less rubber, flexible and somewhat stretchy, that you sort’ve

turn

inside-out as you demold; silicone, flexible but less stretchy, you

generally make much thicker and have to cut a seam in one side for

demolding, which makes

wrapping in plaster gauze –a mother mold- necessary

to hold it closed during casting.

The big problem I’ve encountered with silicone so far is a

strong

tendency to want to leave gaps in places like under the chin as you

spread the

putty while making the mold, forcing you to do a lot of handwork on

your

castings, patch the gap -which is very

difficult to do smoothly- or start over

with making a new mold if your master is in any shape to.

I probably should have started over with the doll and the plasticine and avoided the copy degradation –any flaws tend to add up as you copy copies- but that would have been completely from scratch, as getting it out of the mold had destroyed the hairdo and I’d already cleaned the rest off the doll – besides, I could paint thin layers of plaster over the shoulder seams and neck crack, as I mentioned above, and do some careful sanding, and have a very good copy to work with, which I did.

There was probably more copy degradation in the end than I should have tolerated, but the second-generation copy I had by the end of the day was still higher-resolution/quality than the big hair Barbie, which I’d been satisfied with at the time… -Don't forget that I'd been waiting for nearly two weeks, too...I do strive for

perfection, knowing I can’t

have it, but you have to

learn when to stop chasing diminishing returns and move

on the next work with what you’ve learned, so I commenced the first

candle -

but I've taken good care of the master copy since, just in case.

-I decided to investigate getting the latex mold back into usable

condition,

too...

(Here’s a shot of

two subsequent candle

casts in front of the mold and mother together, with a third candle

cooling…)

I

did the latex application

over the cut piecemeal because, you may have noted in the pics from

cutting it

open, the mold wants to hang wide open at the cut/seam and some of the

tape had to stay holding it shut shile the rest fried. I

(carefully) did

the same at the bottom right before bed hours later, and got the middle

area the

next day after the top and bottom were credibly dry enough to hold the

rest shut and lined up right.

I was just going to have to cut it open again to demold, so why

bother?

Because it needed a mother mold to hold it shut, and this made sure it

stay shut and lined up right -tape would have fouled the mother up

several ways- and built a slight ridge

on the surface to help orient the mold just right on reuse, and made it

that

much thicker around the seam. With a really snug mother, it'd

work same

as a thick silicone mold, I thought.

This was the last

casting of this figure I’d planned for now, anyway –all

the colors and scents were now covered with with this one- and I

suppose the time/effort of the salvage attempt wasn’t

entirely wasted, with a very good candle to show for it, and an advance

in my

knowledge of things you can and can’t do with a latex mold.

---

---

|

| Top Home |